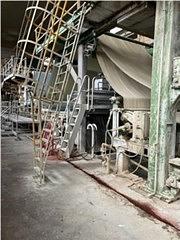

Packaging Kraft Paper (PKP) machine - MM Kwidzyn, in Poland

MM Količevo d.o.o. – Board Machine 2

Basic data:

Three layer board (top/middle/bottom)

Coating:

1. Top: rod – Varibar (6 gsm)

2. Top: Airknife (8-12 gsm)

3. Top: Blade – Combiblade Jagenberg (9-12 gsm)

4. Back: rod – Varibar (5-6 gsm)

Board type: GD2, GD3, GT2, GT4, GC2,GC4, UC4

Width on Pope reel : 2240 mm

Speed range: 70 – 200 m/min

Grammage range: 190 – 550 gsm

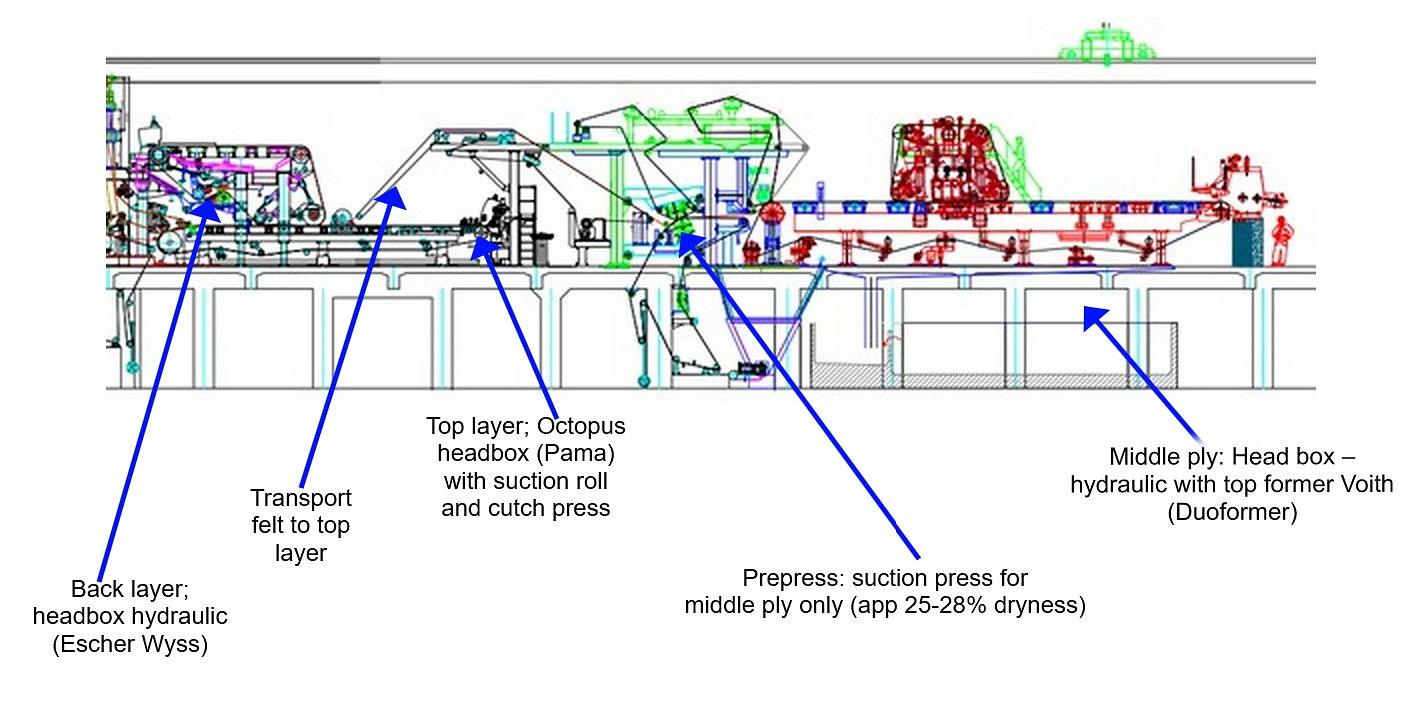

BM construction:

Wet Section

- Middle ply: Head box – hydraulic with top former Voith (Duoformer)

- Prepress: suction press for middle ply only (app 25-28% dryness)

- Transport felt to top layer

- Top layer; Octopus headbox (Pama) with suction roll and cutch press

- Back layer; headbox hydraulic (Escher Wyss)

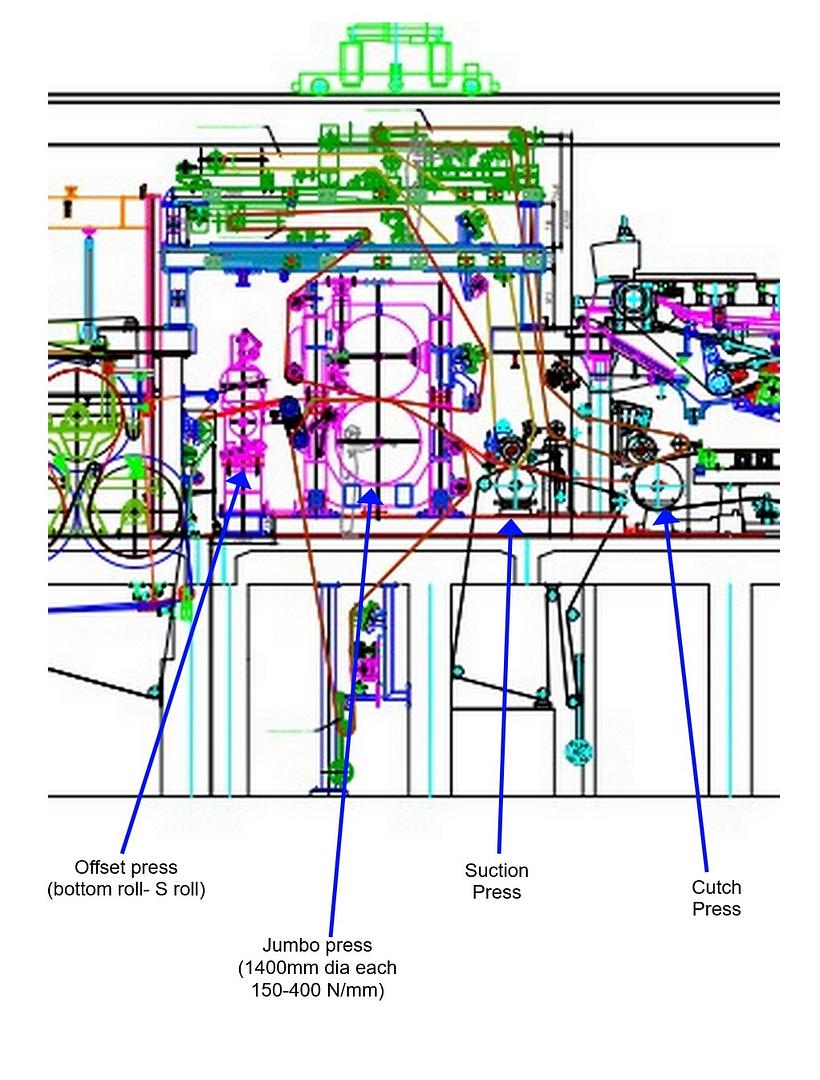

Press Section

- Cutch press

- Suction press

- Jumbo press (1400mm diameter each, 150-400 N/mm)

- Offset press (bottom roll- S roll)

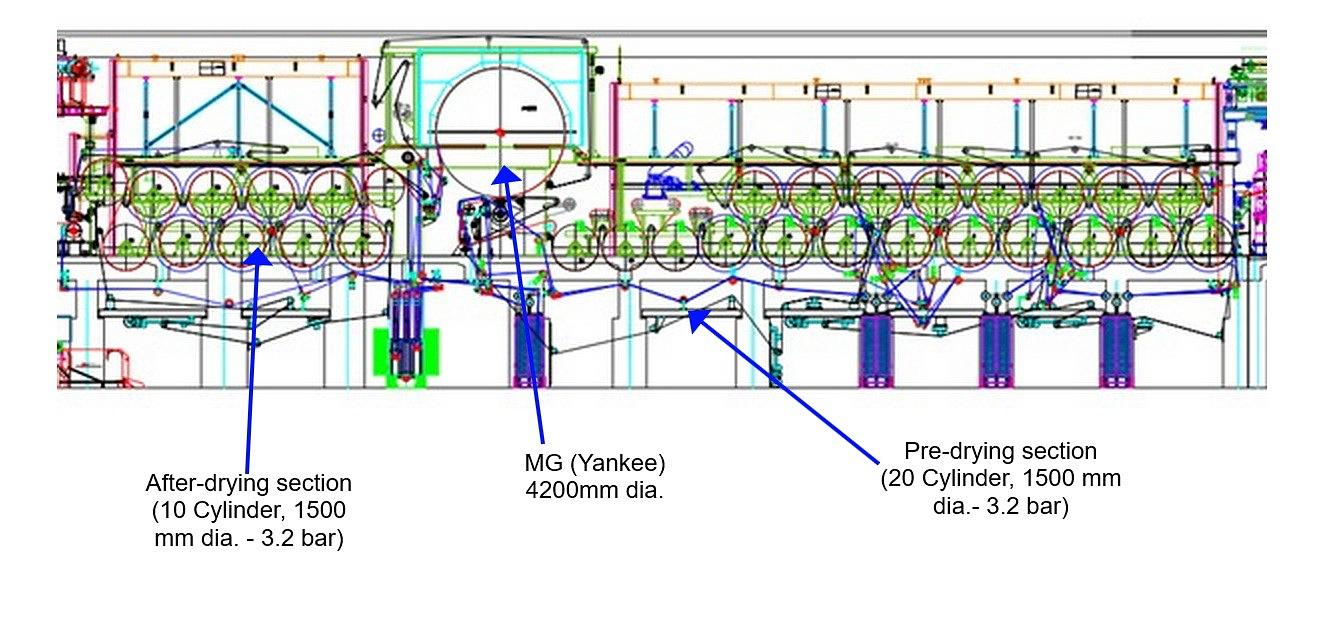

Drying Section

- Pre-drying section (20 Cylinder, 1500 mm diameter, 3.2 bar)

- MG (Yankee) 4200mm diameter

- After-drying section (10 Cylinder, 1500 mm diameter, 3.2 bar)

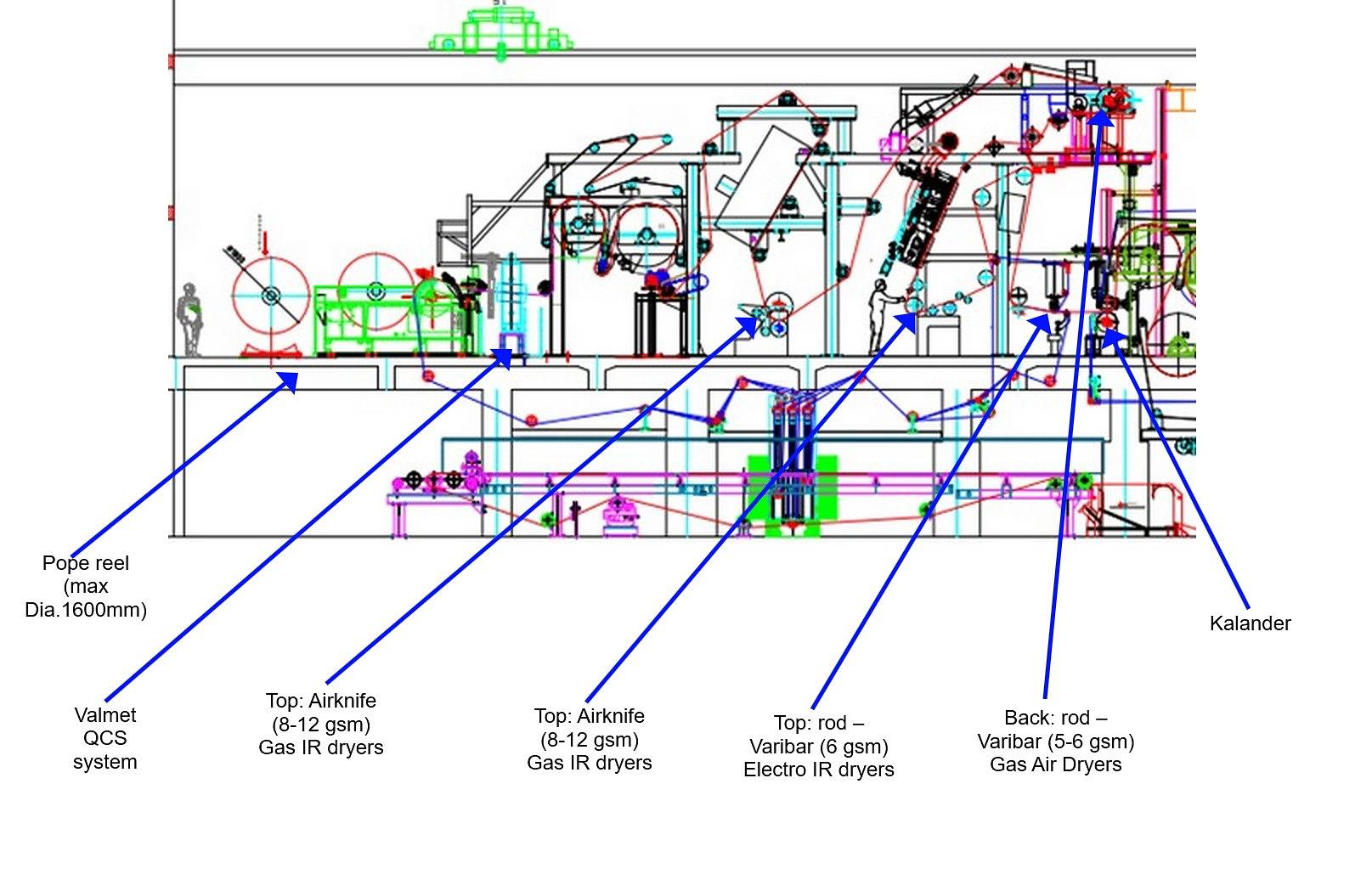

Coating Section

- Kalander

- Coating:

- Top: Airknife (8-12 gsm) Gas IR dryers

- Top: Airknife (8-12 gsm) Gas IR dryers

- Top; Blade – Combiblade Jagenberg (9-12 gsm) Air dryers

- Back: rod – Varibar (5-6 gsm) Gas Air Dryers

- Valmet QCS system

- Pope reel (max diameter 1600mm)

MIDDLE LAYER

MIDDLE LAYER HB

PRE PRESS

TOP LAYER

BOTTOM LAYER

CUTCH PRESS

NO 1 PRESS

NO 1 PRESS

JUMBO PRESS

OFFSET PRESS

P. DRYING

IR DRYING

IR DRYING

YANKEE

AFTER DRYING

COATING AREA

KALANDER

KALANDER

VARIBAR 1

AIR KNIFE

AIR KNIFE

VARIBAR 2

BLADE COATING

KOREKTURNA

KOREKTURNA

MEASURING HEAD

POPE

POPE

REWINDER