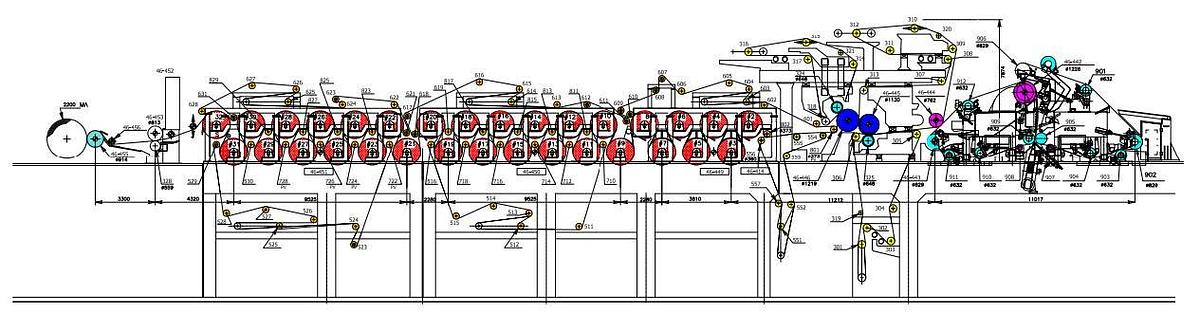

5.4 Meters (212 in) Packaging KRAFT Machine #46835

5.4 Meters (212 in) Packaging KRAFT Machine #46835

Available quantity:1

Description

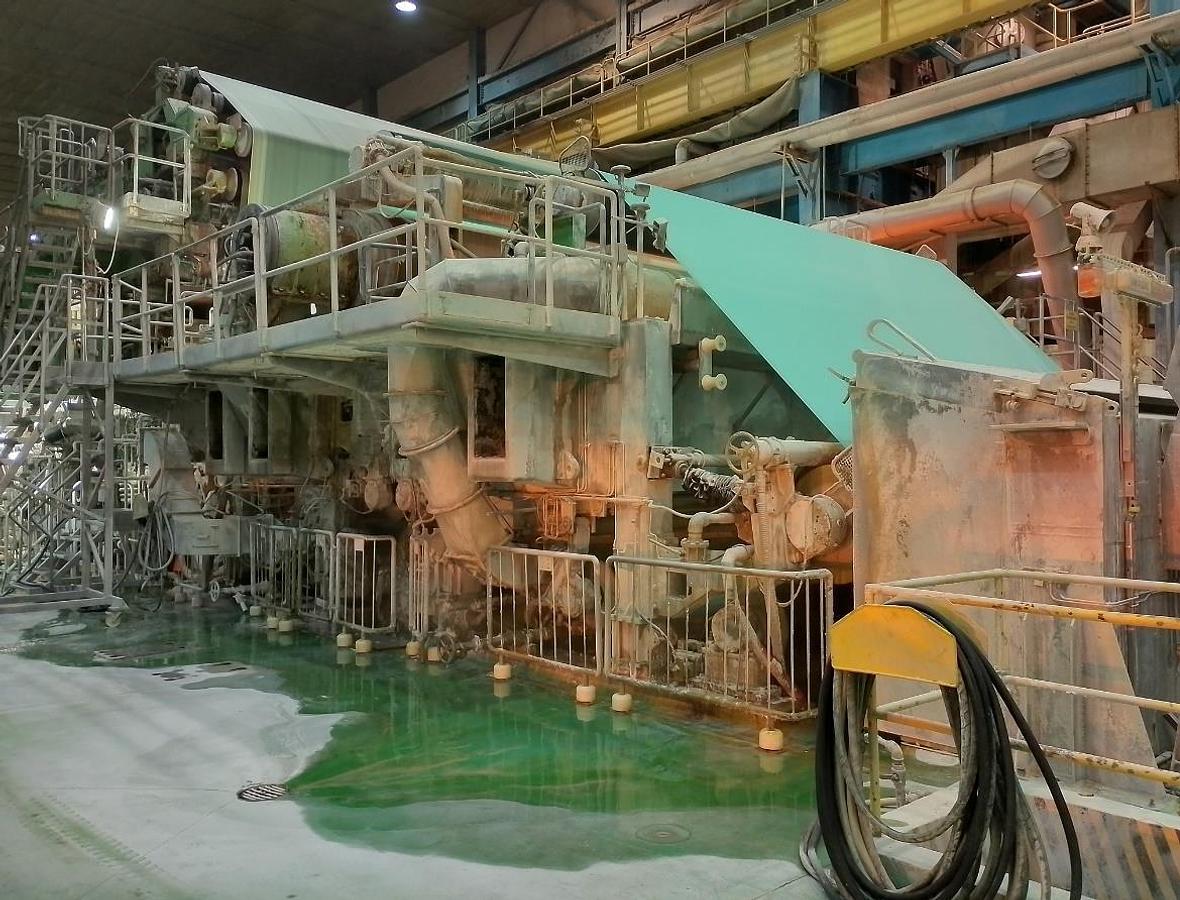

5.4 Meters (212 in) Packaging KRAFT Machine

5400mm (sheet width at the reel) Packaging Kraft Paper (PKP) machine located in MM Kwidzyn, in Poland and part of MM Board & Paper since 2021. Machine stopped in Jan/24.

Manufacturer: Beloit

Machine start-up: 1988

Machine capacity: 75.000 t/y

Machine speed range: 450 - 1000 m/min

Wet End

Headbox – Beloit, vertical position, witdh of stock outlet: 5892 mm, equipped with Measurex Thermatrol (basis weigth CD profiling system controlled from QCS) – 59 zones

2 wires – 1st wire (19,54 m x 6,05 m) and 2nd wire (16,50 m x 6,05 m)

Dewatering foils – 9 pcs, ceramic

Deflector – ceramic

Vacuum box – approx -20 to -25 kPa operation vacuum

Couch roll – 46-442, driven, two suction chambers (low up to -45 kPa and high up to -70 kPa operation vacuum)

Guide rolls

Bow rolls – #907 and #908

Cleaning shower system

HP shower system – 2 pcs

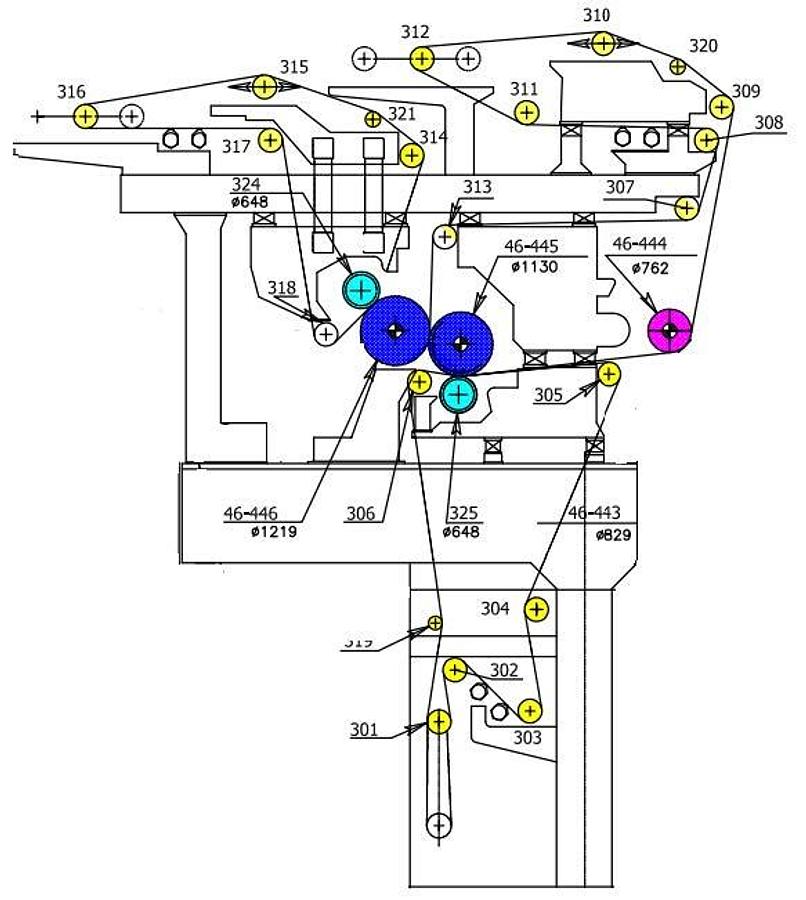

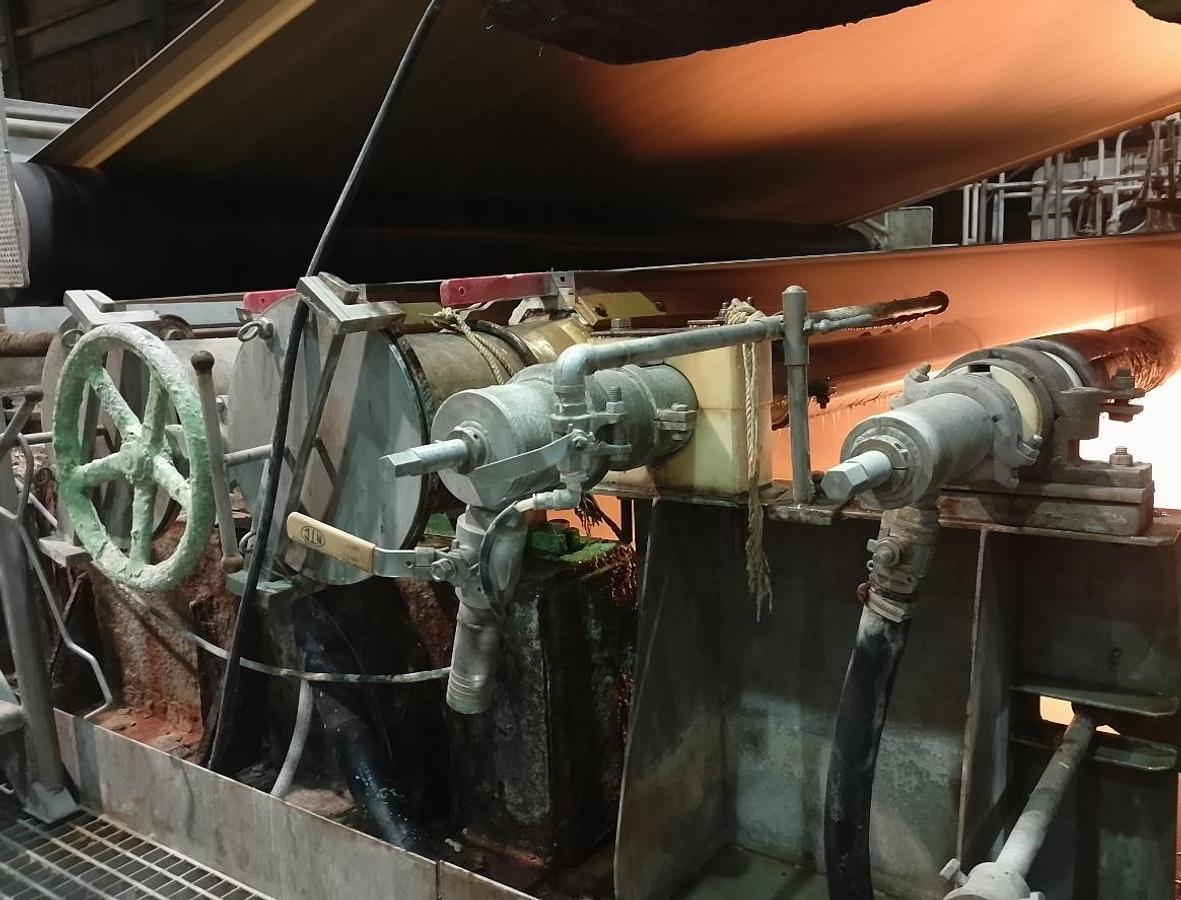

Press Section

Pick up roll – 46-444, driven, one suction chamber (up to -70 kPa operation vacuum)

Suction roll – 2nd press, 46-445, driven, three suction chambers (low up to -42 kPa and high up to -70 kPa operation vacuum)

1st press Venta roll – #325, undriven, crown control, blind drilled

Central roll – 46-446, driven, ceramic

3rd press Venta roll – #324, undriven, crown control, blind drilled

Steam box – ABB, 72 zones, controlled from QCS

Double doctor holder – at central roll

6 Uhle boxes – two installed at each felt (one slot)

Lubrication shower system – two showers at each felt

HP shower system – one shower at each feltAsienka01@@@

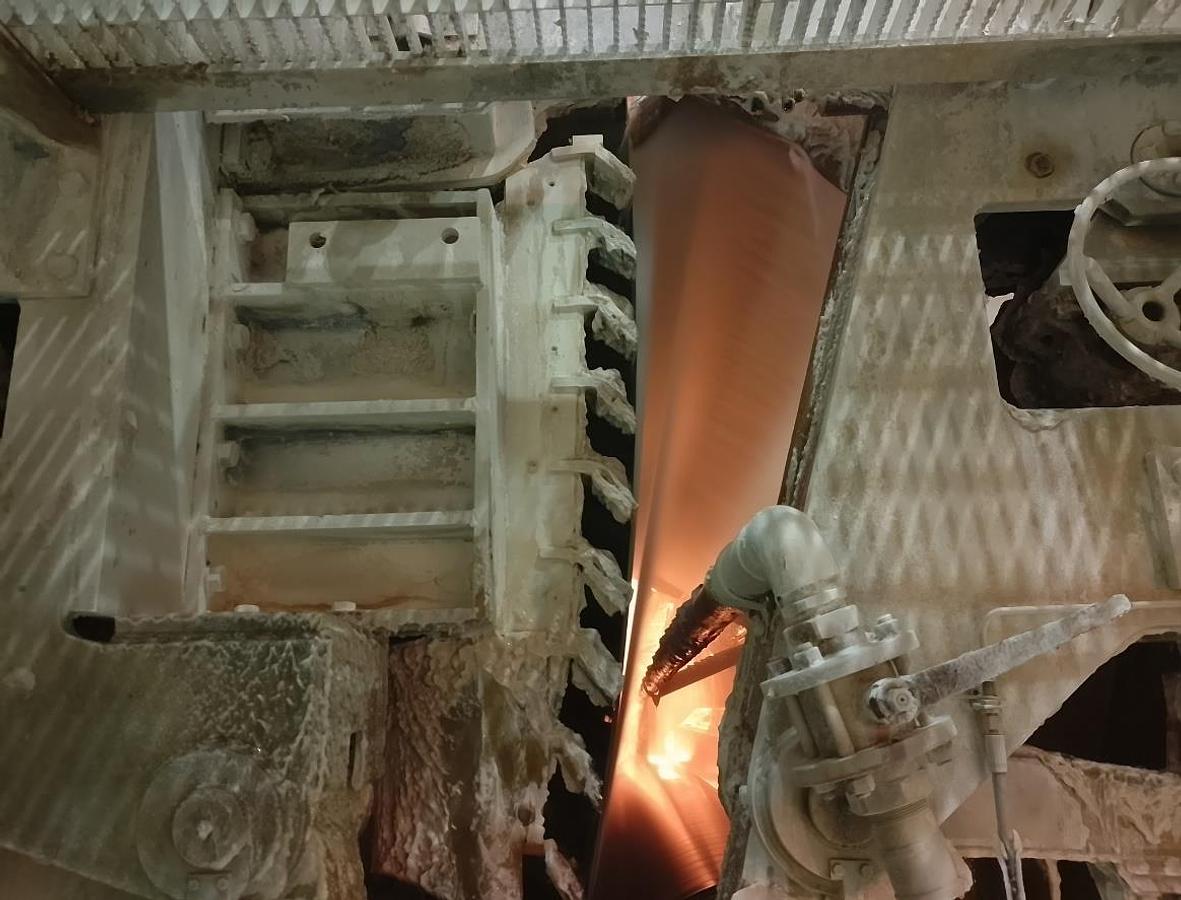

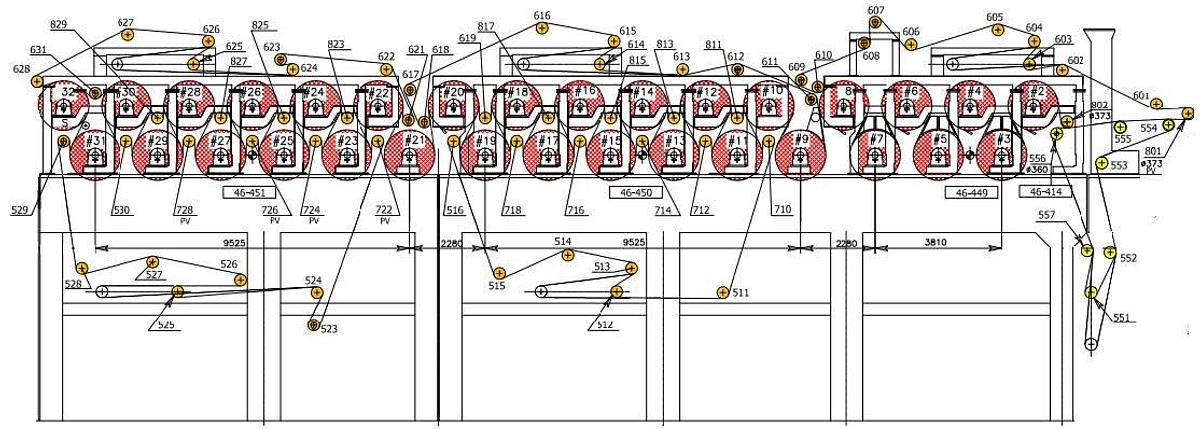

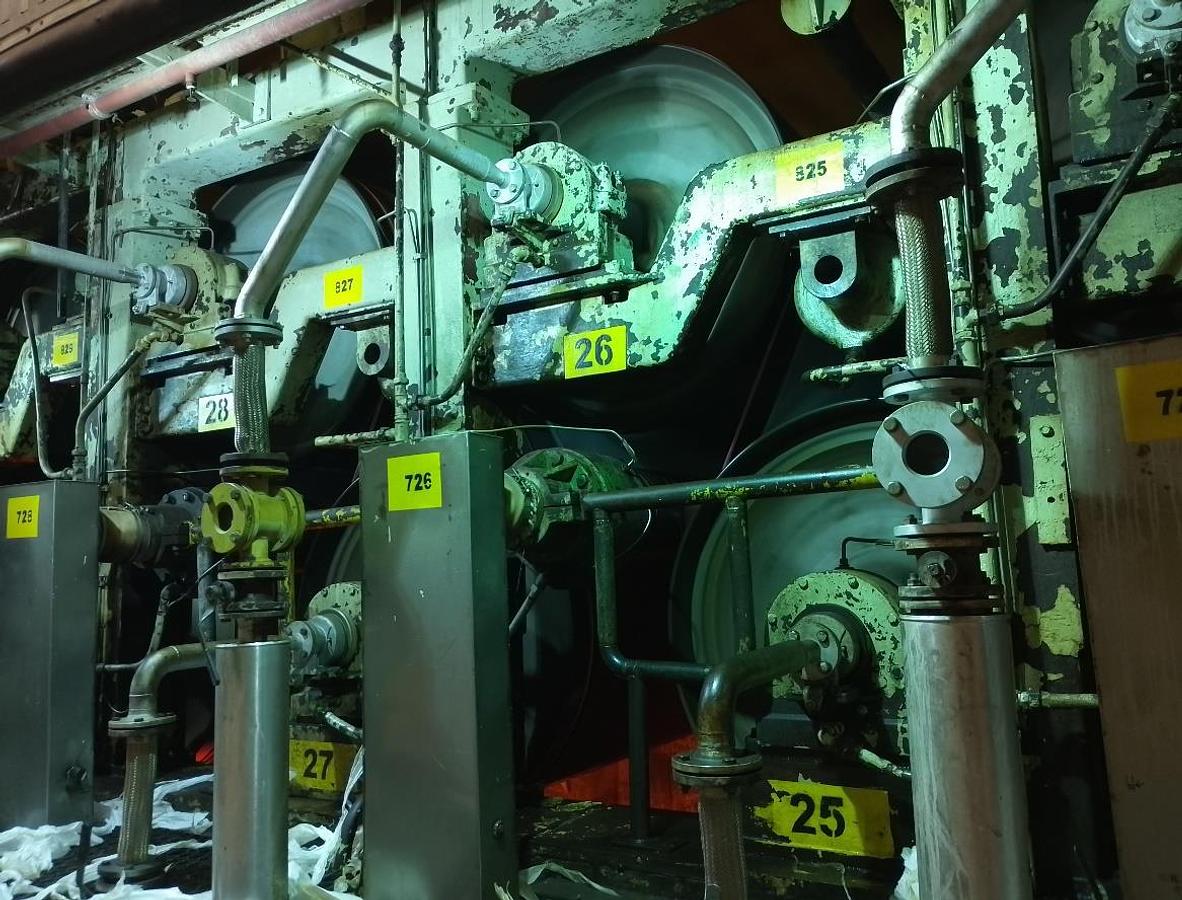

Dryer Section

31 drying cylinders – DIA 1524 mm, three drive groups (1st group – 7 drying cylinders + 11 guide rolls, 2nd group – 12 drying cylinders + 24 guide rolls, 3 rd group – 12 drying cylinders + 21 guide rolls + 4 PV rolls), 6 steam groups, cascade system – steam 5 bar, steam supply on drive side, condensate outflow on front side

Six drying fabric loops

Hood – panel construction, half glazed, side guides, indyvidually or sectionally controlled from benchboard

Water jet knife – FastPap, threading to calender stack

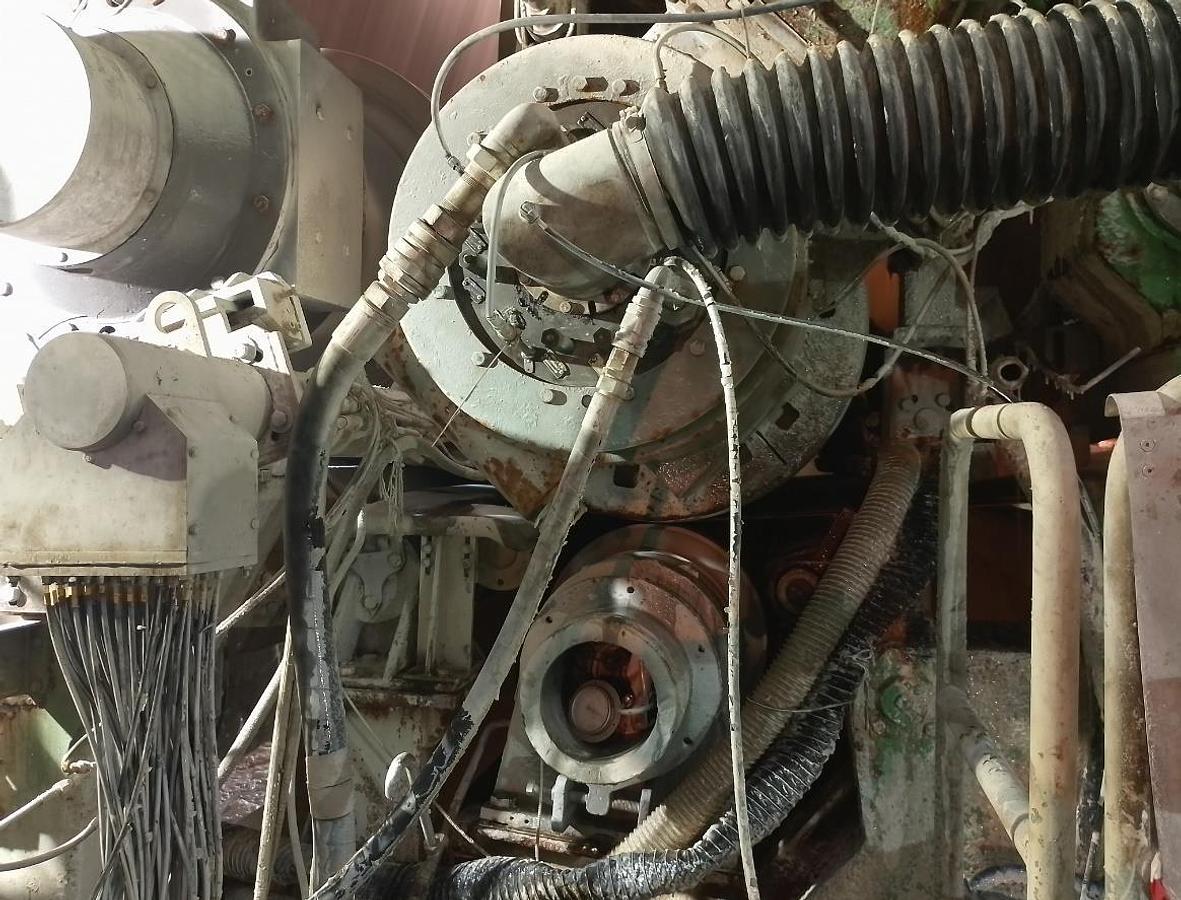

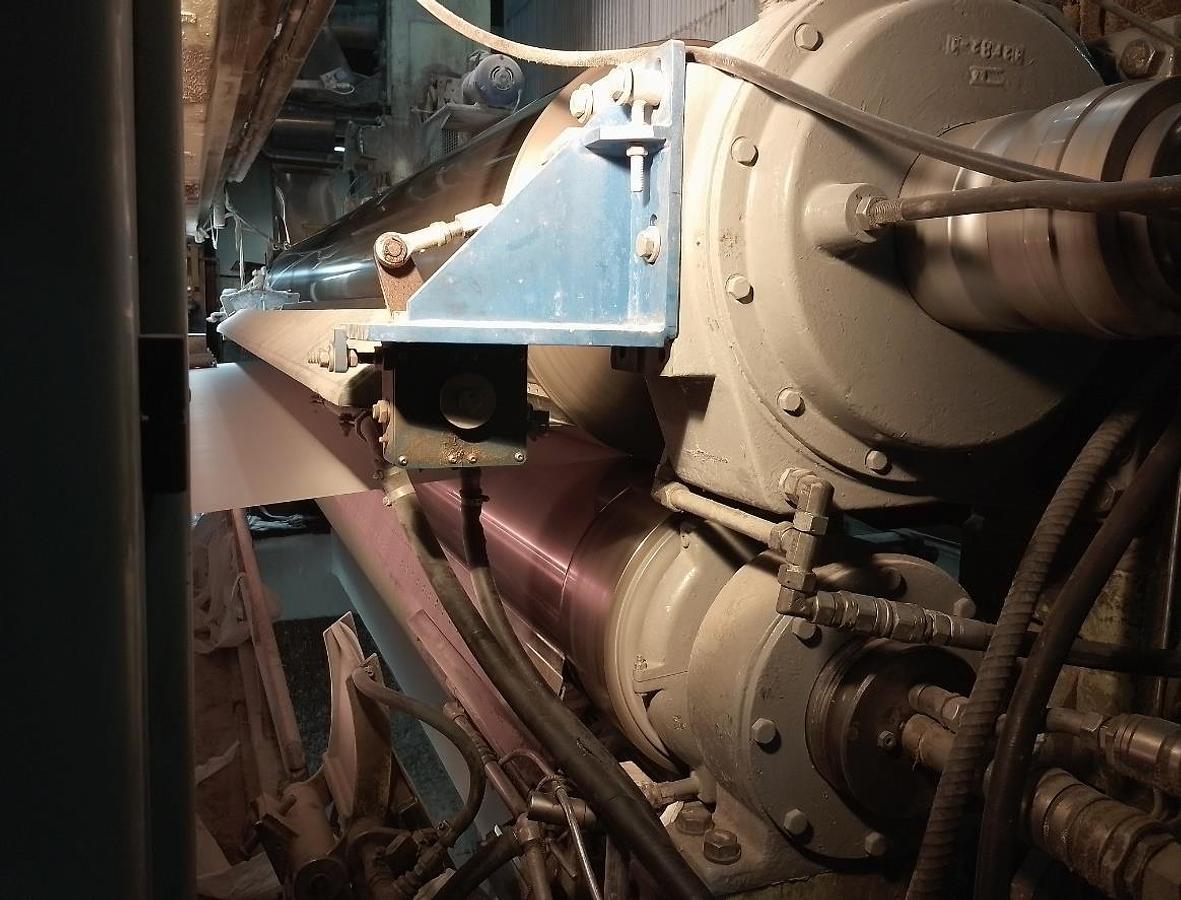

Calender & Reel

2 steel rolls calender (option for 4 rolls - 2 rolls dissmantled)

CD caliper profiling system – Measurex, Cal-coil, 56 zones

QCS system – ABB, network platform 1200: caliper, moisture, basis weight, ash CD and MD measurement, 800xA V6.0 (2 operator stations, 1 engineer station)

Web inspection system – ABB, 12 cameras

Color mesurement – Xrite ERX50, Macbeth, measurement of the opacity, brigthness, shade

Reel – steel, spiral grooved

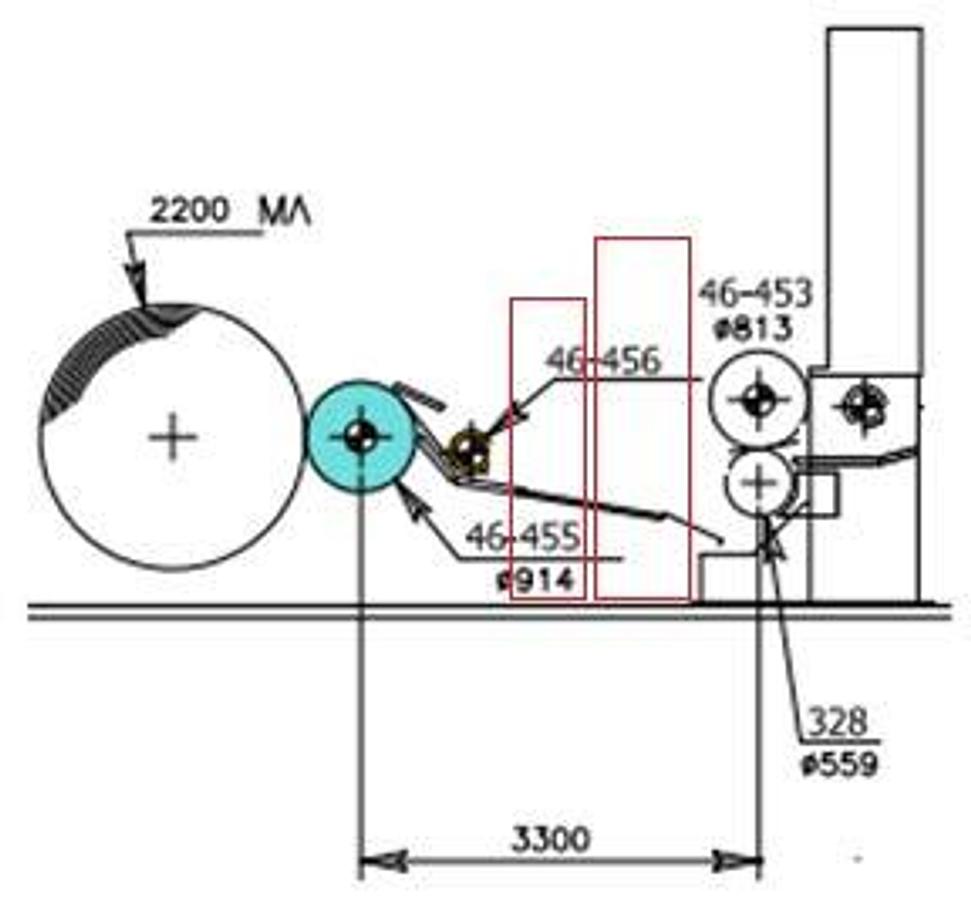

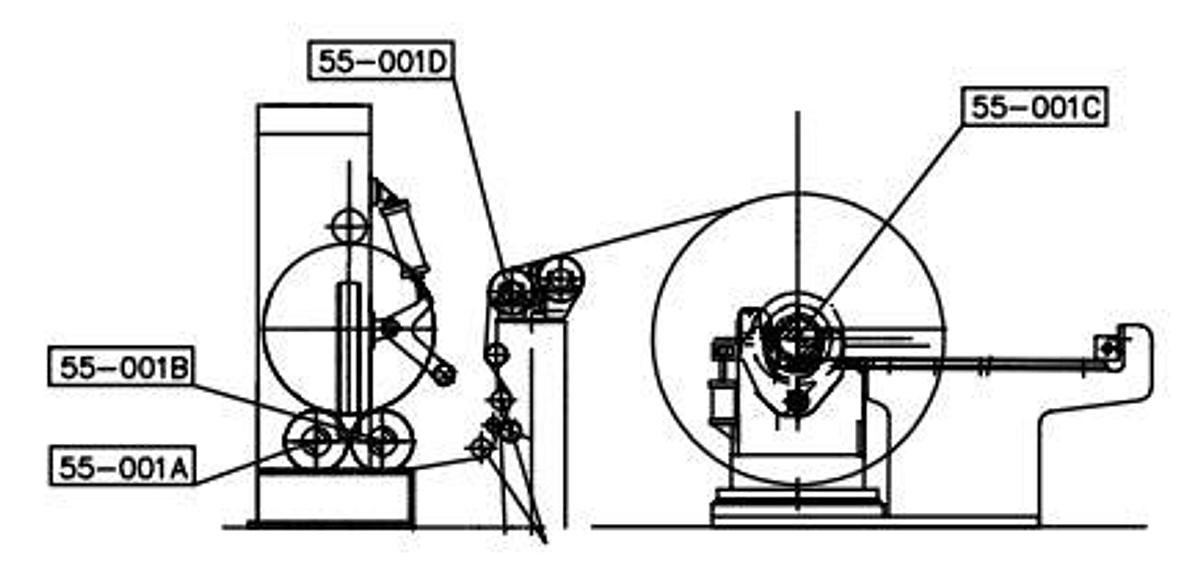

Winder

Max speed – 2000 m/min

Max reel width – 5450 mm

Max reel diameter – 2200 mm

Roll sizes: max dia 1400 mm, max width 2350 mm, min dia 600 mm, min width 190 mm

12 disc knives

Core sizes: dia 70 mm, 76,5 mm, 150 mm, 152,8 mm

Quality:

- Bleached packaging kraft paper

- Unbleached packaging kraft paper

Grammage range

- Bleached PKP - 28 – 60 gsm

- Unbleached PKP - 28 – 80 gsm

Major rebuilds:

- 1994 – headbox and wire section replacement, modification in 1st and 2nd drying group, cal coil installation (caliper CD profiling), tail threading installation

- 2001 – all gearboxes replacement (speed over 1000 m/min)

- 2002 – DCS, QCS and steam box installation

Specifications

| Manufacturer | BELOIT |

| Year | 1988 |

| Condition | Used |

| Stock Number | 46835 |